Links between humidity, temperature and lighting - VPD

09/2019

In growth protocols there are multiple links and relationships between different parameters (air, water, lighting, fertilizer etc.)This next article is a bit more on the technical side and I hope will interest you. My main goal is that after reading, you understand the importance of the links between the different parameters and why it is vital to have a comprehensive understanding of the whole protocol when it comes time to address, build or improve an existing one. We’ll talk about a particular part of the growth protocol which well demonstrates the links between parameters and has a significant effect on growth results. Let's start by defining 4 technical terms which will appear here: 1. Leaf Surface Temperature - LST No better way to explain it than the temperature measured on the surface of the leaf. 2. Relative Humidity - RH The ratio between the water saturation in the air to maximum saturation potential at a specific temperature. This is expressed as a percentage. The process of water movement within the plant and evaporation from different parts of it. Water movement starts with absorption through the roots to stems, leaves and flowers which allows movement of nutrients. Evaporation allows cooling of the plant. 4. Vapor Pressure Deficit - VPD This parameter links ambient temperature, leaf temperature and relative humidity. In fact, this parameter can tell us how temperature and humidity affect the plant - "how the plant feels" in current conditions. This term refers to the difference/deficit between the "vapor pressure" within the leaf and the "vapor pressure" in the growth environment. Relative humidity within a healthy leaf will usually be 100% = saturation, relative humidity in the air of the growth environment will usually be below 100% and leaf surface temperature, in a system that works right, will be lower than the ambient temperature. Using temperature and humidity data, we can calculate "vapor pressure" of the leaf and environment. The difference between them is VPD. An expert grower will know how to control VPD and leaf temperature. This allows control of transpiration rates and nutrient absorption which will ultimately improve crop production. I will try to introduce logic into the process. |

Our starting point is that "vapor pressure" within the growth environment should always be lower than the "vapor pressure" within the leaf. This creates a space with negative pressure which aids evaporation from the leaves. The leaf uses evaporation in order to equalize pressure. The bigger the pressure difference, the more space there is for water in the air of the growth environment and the higher the evaporation rate. This doesn't mean that a higher evaporation rate is necessarily better. We must set this rate for each stage of the growth. The point here is to understand and control evaporation rates. In a plant with dense flowers we usually lower the RH as the different stages progress. Together with lowering humidity levels we must alter environmental temperatures. The change in temperature and humidity will determine the VPD that we are working with. The VPD will determine the transpiration rate. Here the experience and talent of the grower comes into play who will know what transpiration she wants at each stage. Too fast and the plant will feel overloaded or will stop absorbing nutrients. Too slow and it won't reach the maximum nutrient absorption and biomass possible. |  |

Remember that in systems that work well, with healthy plants, the LST will be lower than the ambient temperature. Leaf temperature can be affected by a number of factors: ambient temperature, relative humidity, proximity to light source, air flow, leaf physiology, light spectrum, light intensity and more. Hopefully by this stage you understand the basic terms and logic of parameter relations when managing VPD. In order to connect all this to lighting, we will give an example of two parts of the light spectrum that can affect LST. |

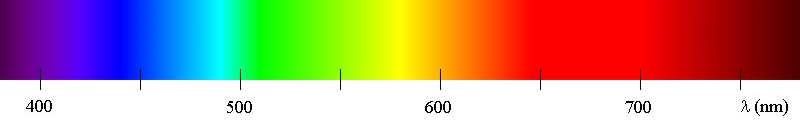

The yellow and green component is in the wavelength range of 500-550 nanometers - In most studies we learn that chlorophyll A & B make most efficient use of red and blue wavelengths (450 and 650 nanometers) but this doesn't mean the plant doesn't make use of yellow and green wavelengths for growth and development. This part of the spectrum is important and can be used. Relative to what happens with blue and red, a smaller part of energy is converted to photosynthetic processes. We can say that the remaining energy causes a rise in leaf temperature. When working with green and yellow components in the spectrum we must be aware of the leaf temperature and make sure it is at the correct ratio to the ambient temperature we are aiming for. | The far red component in the spectrum is in the wavelength range of 720-750 nanometers - As with many other parameters, the far red component in the light spectrum is a dynamic component which changes in intensity according to the seasons and time of day. This component raises the LST. A lighting fixture which allows separate control of far red quantities will help us achieve optimal conditions for VPD levels. This happens by maintaining the LST to ambient temperature ratio. |

To put it all together an example for a method looks something like this: 1. Depending on the growing stage, we will adjust the relative humidity level. 2. Depending on the VPD level we are targeting, we will adjust ambient temperature. 3. Depending on ambient temperature in the growth environment we raise or lower the LST. 4. In order to raise or lower LST we dim the lighting in the far red range (720-750 nanometers). Working with VPD and controlling parameters to the levels we target will allow us to affect the plant. We must be vigilant and pay attention to flower density, internodal spacing and general signs of the plant growth. Remember: VPD can be a measure of "how the plants feels" in our growth environment and we must make sure the plant feels good or stressed according to the grower's needs and wishes. This is one example of the link between parameters of air, light and measurements in the plant, with implications on the building of protocols which integrate to achieve the required result in our plants.I hope I haven't over-complicated my explanations. If I have, then please reread the material. My recommendation is: first, better understand the technical terms and second to study the article, or alternatively, just get in touch with me by email. I wish we all feel as well as our plants and that we will all live in an optimal, sensitive and precise growth environment. Good luck! |